1. What is ion exchange?

Ion exchange was originally a common method for water treatment, but membrane technologies have already fully replaced it in many of its former markets. It still finds usage in industrial applications because it may give high levels of softening and demineralization.

The exchange of ions between two electrolytes or between an electrolyte solution and a complex is known as ion exchange. The phrase is often used to describe the purification, separation, and decontamination techniques that utilize solid polymer or mineral “ion exchangers” to clean up aqueous and other ion-containing solutions.

Ion exchange resins (functionalized porous or gel polymers), zeolites, montmorillonite, clay, or even soil humus can all act as ion exchangers. Cation exchangers, which interchange positively charged ions (cations), and anion exchangers , which exchange negatively charged ions (anions), are both types of ion exchangers. Also, there are amphoteric exchangers that can exchange both cations and anions at once. However, the simultaneous exchange of cations and anions can be carried out more effectively by passing the treated solution through a variety of ion exchange materials or mixed beds that comprise a blend of anion and cation exchange resins.

1.1 Adsorption and Ion Exchange

Ion exchangers can be used to reduce fruit juices’ excessive acidity. Citrus juices have been reported to benefit from this procedure since part of the product’s bitterness is also eliminated.

Using an anion exchanger in OH form, the following equation demonstrates the drop in acidity caused by citric acid. Citrus fruit juices’ primary source of acidity is the three-basic citric acid:

H3Citrate+3ROH→R3Cit+3H2O

2. Ion-exchange resin

Ion exchange resins serve as a medium for ion exchange processes and are insoluble polymers created by crosslinking polystyrenes with various functional groups.

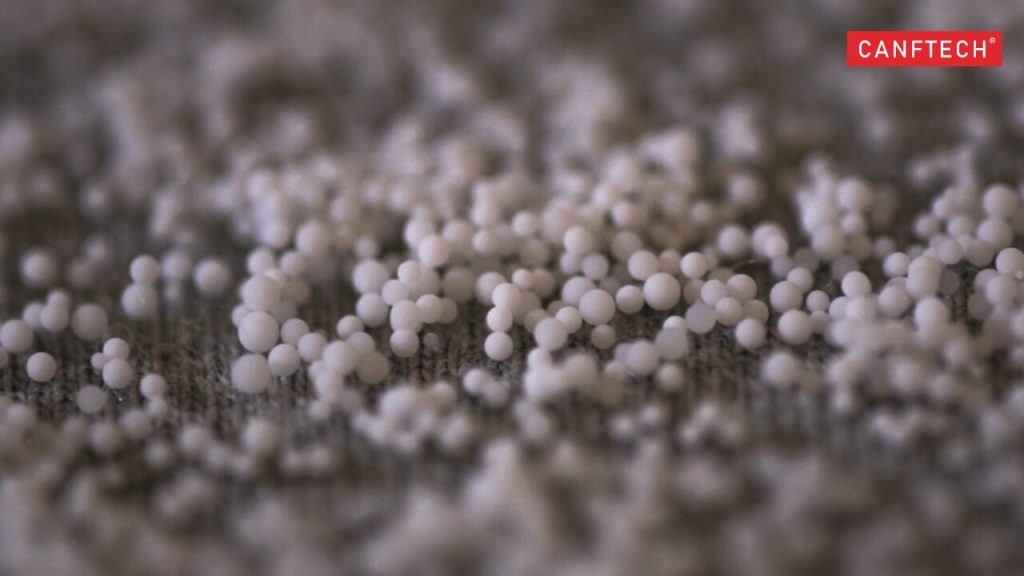

Ion-exchange sites in the resin matrix are where positively or negatively charged ions’ functional groups are attached to create a polymer network. This constructed network may draw ions with opposing charges and speed up the ion exchange process. The resins are often present as white or yellow porous membranes, granules, or microbeads. In ion exchange processes, their pores offer a significant surface area to capture and release the ions .The resins expand by absorbing the solution when submerged in it. However, the degree of swelling is influenced by the ion concentration in the solution as well as the polymeric makeup of the resins.

3. Applications of ion exchange resins

Ion-exchange resins are a practical and affordable choice for the purification, separation, and decontamination of ionic species-containing solutions. Ion exchange procedures are also less expensive, and the exchange resin may be renewed by simply treating it with a solution that has too many extra displaced ions.

3.1 Purification of Metal

Ion exchangers are frequently used to separate materials like uranium from plutonium. Ion-exchange has been employed often for many years, but solvent extraction has also significantly aided in the separation of the lanthanide and actinide group of elements. Ion exchange has significant uses in both the reprocessing of radioactive waste and the processing of nuclear fuel.

3.2 Pharmaceuticals

Ion exchange resins are employed in formulations for the controlled release of active components, the purification of antibiotics from fermentation broths, and the masking of some medicinal compounds’ offensive tastes and odors.

Read this: Water for pharmaceutical industry

3.3 Beverages and juices

Ion exchange resins are used in a variety of ways in the fruit and beverage industries to enhance flavor and taste by removing unwanted ingredients. Trace metal removal, eliminating offensive flavors and odors, decolorizing, and primary water treatment are all common uses.

3.4 Purification of Water

Ion exchange resins are employed in this procedure to take hazardous heavy metals like lead and cadmium out of the solution. De-mineralization of cationic and anionic impurities can be accomplished using mixed bed resins with intermittent regeneration cycles.

3.5 Catalysis

In a variety of chemical processes, such as inversions, hydrolysis, hydration, and polymerization reactions, ion exchange resins are an effective replacement for acids, alkalis, and metal ion catalysts.

3.6 Nylon production

Adipic acid is a chemical used to make the polymer nylon. Nylon is created using almost 60% of the 2.5 billion kg of adipic acid generated each year. Copper and vanadium catalysts, which may stay inside the acid, are necessary for the formation of adipic acid. But it is essential that adipic acid be in its purest form for nylon polymerization to proceed correctly.

3.7 Gelatin & collagen production

Ion exchange resins remove gelatin of organic and inorganic substances, enhancing the color, flavor, and aroma of the meals, medications, nutritional supplements, sweets, and delights we eat. A protein-based material called gelatin is made from the bones, skin, and other tissues of many animals, including cows, pigs, chickens, and other creatures. By-products from the production of leather and meat are used to make gelatin and collagen. Numerous amino acids, including glycine, glutamic acid, proline, alanine, arginine, hydroxyproline, hydroxylysine, and other important amino acids, are found in both gelatin and collagen.